A New Approach to Sailing

For the purpose of convenient maneuvering in harbors and in extended periods of unfavorable winds and for emergencies, cruising sailing yachts are typically fitted with inboard or outboard combustion engines connected to a propeller via a transmission as secondary means of propulsion. The alternative of electric motors provides offer benefits such as clean operation, low noise and easy handling. Their power sources are typically batteries charged with shore power. In climates with ample sunshine, on-board solar panels may present an alternative for charging the batteries, and may even enable electric propulsion, when shore power is unavailable. We explore this idea using a Singapore registered Maxi 77.

Deck and Interior of Maxi 77 Sailing Yacht

Environmental Factors

Sunlight Exposure in Singapore:

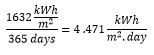

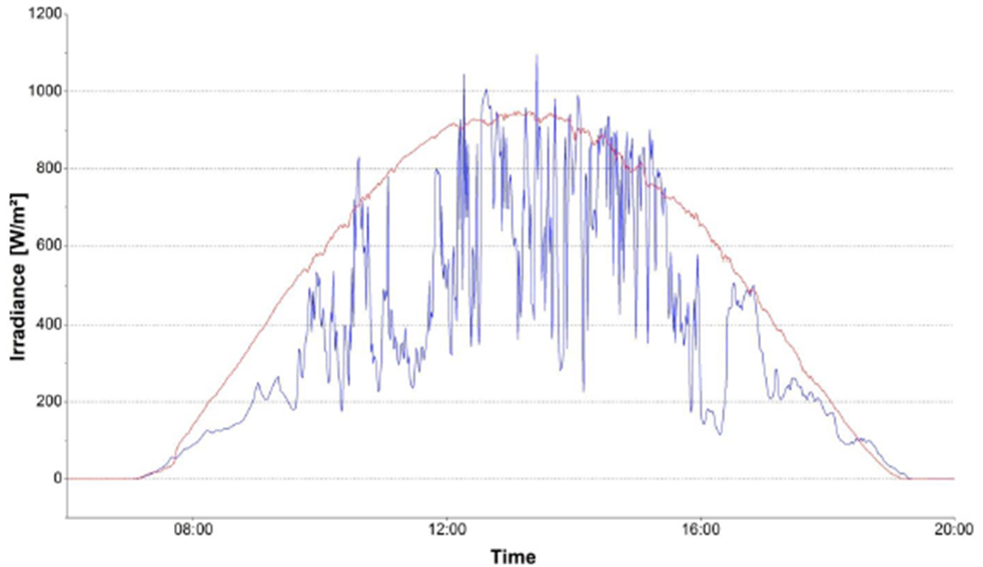

The average solar irradiation for a typical day is much lower than for a clear-sky day due to changing cloud cover. The annual irradiation in Singapore is 1632 kWh/m^2. The average solar radiation per day is thus:

Compared to a daily theoretical power output of the sun of about 24 kWh/m^2 adjusted for sea level conditions, we have effectively about 4.5 hours of full sunlight per day in Singapore.

Sea Conditions:

The harsh environment of the open sea requires a ruggedized truss to withstand the movement of the boat; high wind speeds; prolonged exposure to salt water; as well as steadily uphold the solar panels.

Design and Performance

The panels are mounted on a stainless steel truss that doubles as cockpit roof. Three major design constraints of this truss were to avoid impedance of passenger movement, avoid interference with the boom, and leave space for the boat’s backstay. The backstay is a metal cord that runs from the mast to the rear of the boat to hold up the mast. These constraints led us to mount the panels 2m above the seats to allow for unhindered passenger movement in the boat. Based upon the cockpit geometry two panels were transversally mounted and one was longitudinally mounted. The backstay runs between the two transversally mounted panels and the longitudinally mounted panel. The panels’ wires are fed through the poles into the boat’s hull.

CAD Rendering of Truss Design with Solar Panels

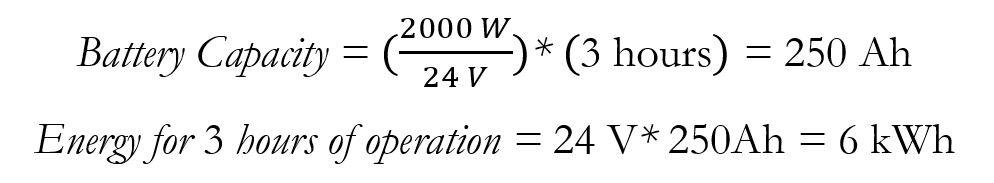

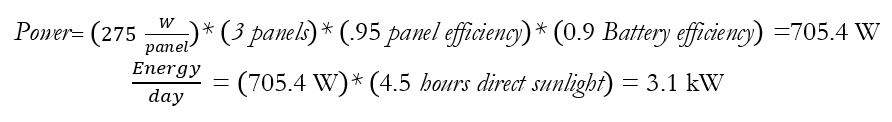

To operate the boat exclusively under electric power for three hours continuously, the vessel was fitted with a 2000 W electric outboard motor. Power requirements for a boat is about 1kW per ton of displacement. Two 12V lead acid batteries are used in series for energy storage.

Three 1x1.65m, 275W monocrystalline solar panels are sufficient to power the motor. Based on the calculations below, we can charge our 6kWh batteries in less than two days. However, the required amount of surface area required for the panels does not scale with the size of the vessel. For a vessel larger than 12m, 24kWh are required which roughly translates into a solar panel surface are of 19.25m^2. This indicates our solution is only valid for small vessels.

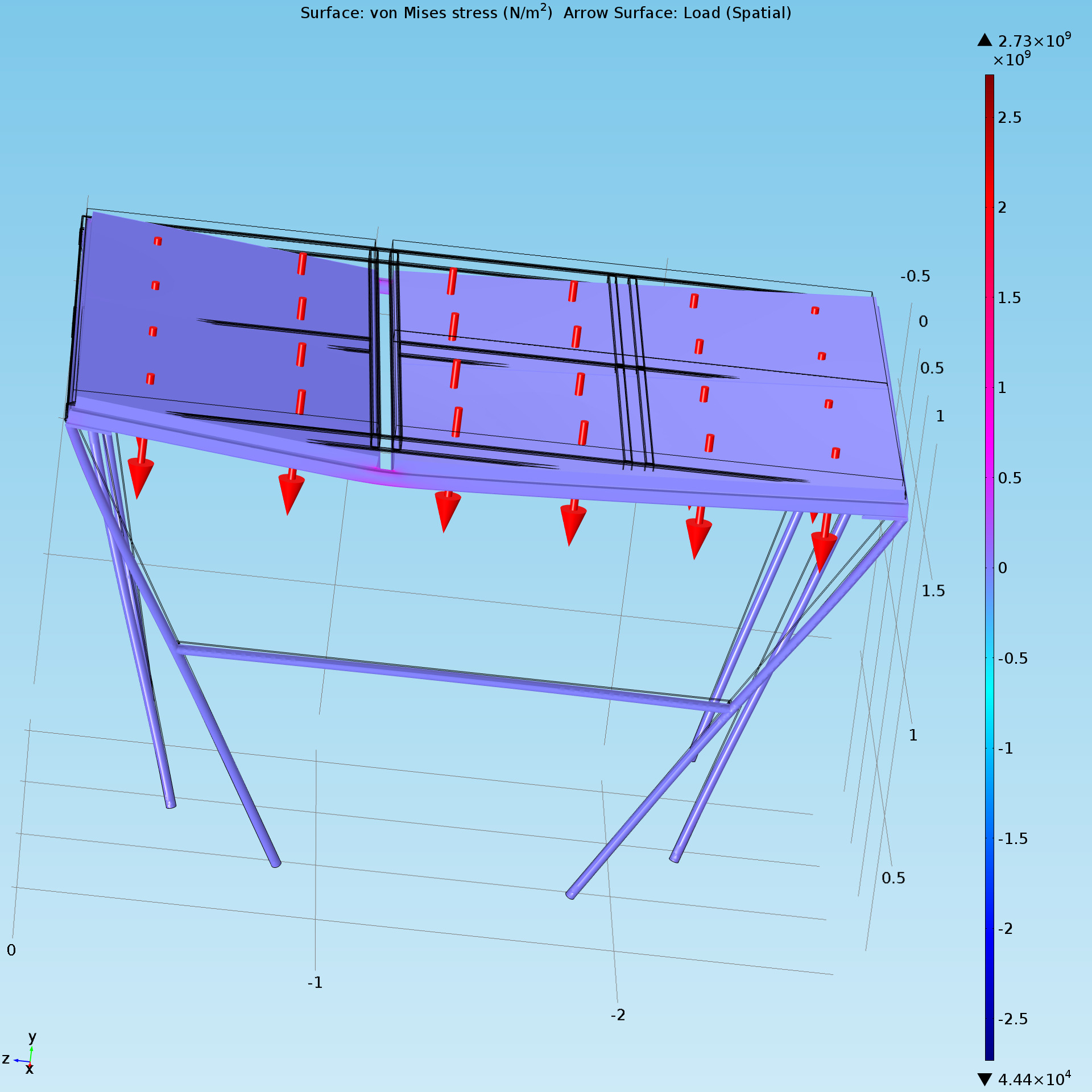

Wind Load Analysis

To examine a worst-case scenario for wind forces acting on the truss, Force 9 winds on the Beaufort Scale are simulated, which reach velocities of 21–24m/s. We expect the most stress on the truss when the wind perpendicular to it. The force is loaded on top of the panels and the response is scaled to highlight the areas of deformation. From several simulations, it becomes evident that the structure deforms no more than 2mm in the region with the most stress.

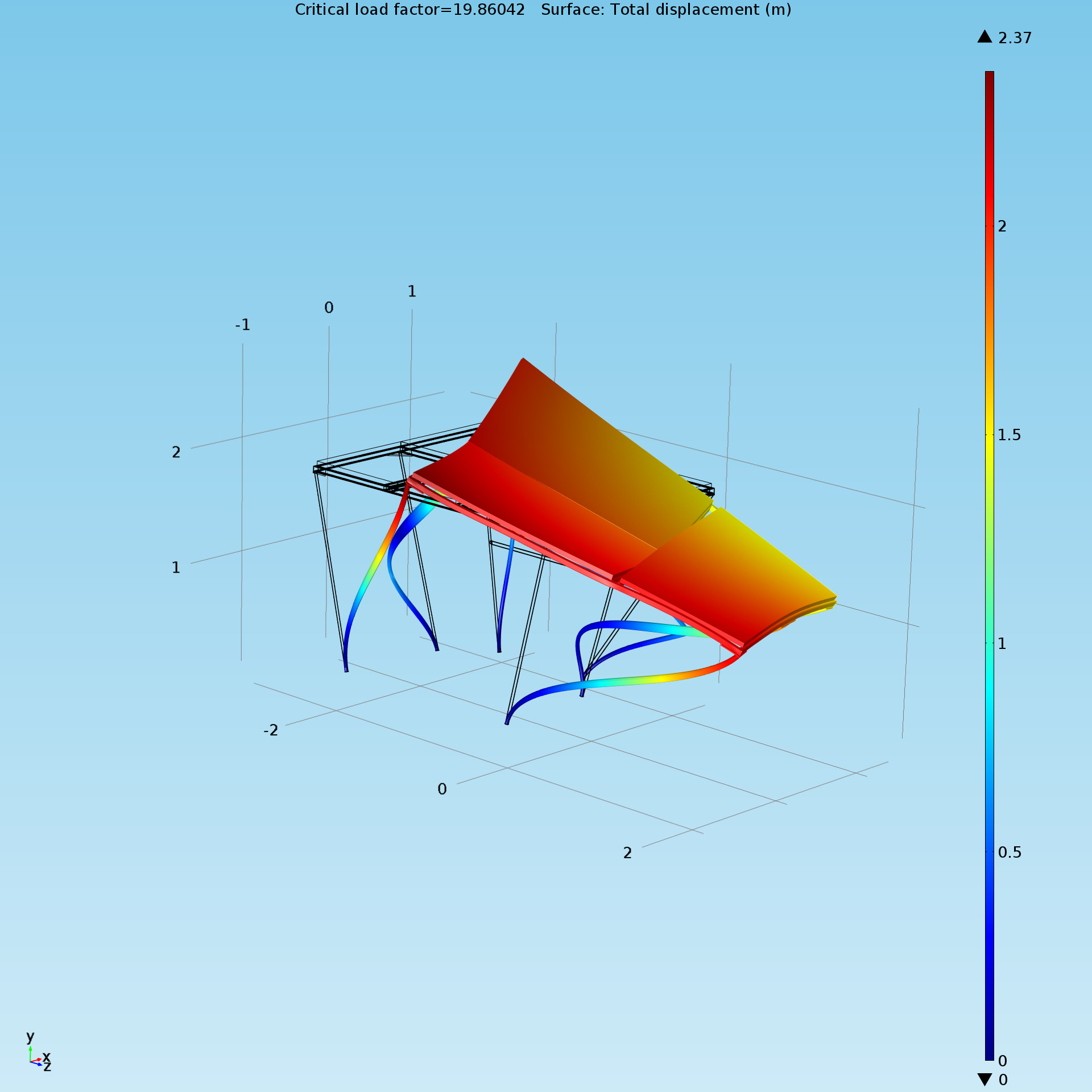

The figure below shows the results of a buckling load simulation, which calculates the load when the poles of the truss fail and illustrates how they deform. The structure rotates towards one corner as it collapses due to the asymmetrical arrangement of the solar panels. Fortunately, the buckling load of the poles is approximately 19 times higher than the load occurring in Beaufort Force 9 winds. This indicates that it is unlikely for the truss itself to fail if the boat experiences severe wind and weather conditions.

Conclusion

The target vessel underwent extensive testing in January 2015, including voyages to six islands within Singapore, and to the islands of Batam and Bintan in Indonesia. The theoretical range of three hours under full-throttle electric-only operation with a battery capacity of 250Ah at 24V and a 2kW motor calculated in is experimentally confirmed. We also verified a full recharge time of the batteries of two days. A re-charge time of two days limits the daily cruising range in wind-deprived conditions, but the three 275W panels proved sufficient for hybrid wind/solar operation in practice during the test runs.

I want to acknowledge the generous support from National University of Singapore and Rezeca Renewables that the Frogworks team received. Additionally, I would like to give special thanks to my partner on this project Eric Yee and our supervisors Martin Henz and Joerg Weigl.